The implementation of integrated simulation technologies plays an increasingly important role in advanced engineering today, as more and more manufacturers want to evaluate design performance before going into production.

- Virtual testing and validation that tests the behavior of products in different environmental and operating conditions.

- Manufacturability that simulates the proposed manufacturing process and enables engineers to optimize the cost, quality and performance of products.

Broadly speaking design simulation reduces the costs and time of product development, improves quality, and avoids the need to do expensive, recurrent physical prototype testing.

However, in addition to automation simulation, virtual prototyping, and testing will determine whether designs will perform as intended. The most efficient way to conduct virtual prototyping is with integrated simulation tools that address issues that are present in software, because this eliminates the costs associated with prototype failure.

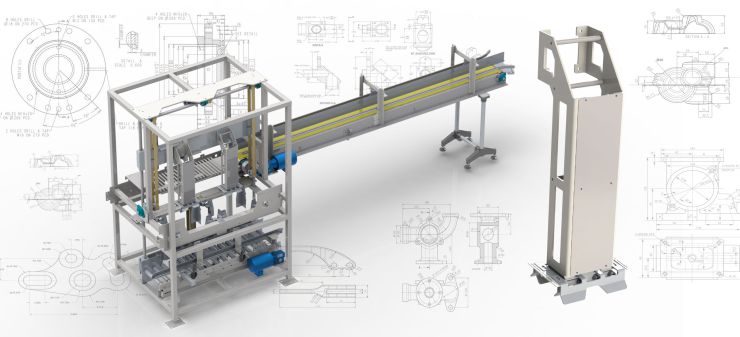

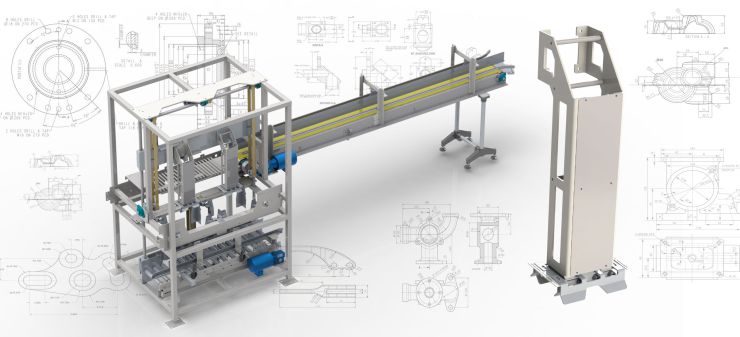

The experienced, highly skilled engineering team at CREO TECH develops a concept and then performs simulations of the traditional motion-control aspects of the process. They factor in the actual loads, inertias, control processing and other elements to develop an accurate simulation. Changes to the process can be made easily to show alternatives.

If necessary, the CREO TECH team will develop a prototype of the most difficult parts of the automation for proof of concept. Because of our comprehensive inventory of components, our excellent supplier networks and relationships, and our in-house manufacturing capabilities, we can usually perform this cost effectively and incredibly quickly.